Advanced instrumentation for braking system testing

TecSA R&D is equipped with state-of-the-art instrumentation designed to support the execution of comprehensive and accurate tests on dynamometric test benches for braking systems.

Our continuous collaboration with TecSA allows us to keep our equipment constantly updated with the latest technologies and the most rigorous standards.

Whether it’s homologation tests, manufacturer specification validation, or customized testing, our advanced instrumentation guarantees reliable and repeatable results.

By relying on TecSA R&D, you can count on a team of experts and precision instrumentation to obtain crucial data for the development, optimization, and validation of your braking systems.

We offer a complete testing environment, from sample preparation to results analysis, providing specialized technical support at every stage of the process.

Our Capabilities

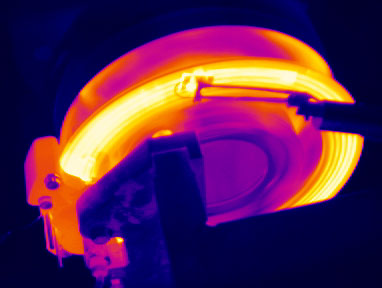

- High-Resolution Thermal Cameras:

Thermal cameras are essential for analyzing the thermal distribution on brake components during operation. We use high-resolution thermal cameras to accurately map the surface temperatures of discs, pads, and calipers. These thermal analyses allow for the identification of hotspots, assessment of cooling effectiveness, and optimization of component design for superior performance and longevity. Data collected with thermal cameras can be used to validate thermal simulation models and diagnose performance issues. - Brake Spray System (Water Cart)

Our spray system is the advanced solution for simulating extreme environmental conditions. This system precisely applies water, saline solutions like salt and magnesium, or other fluids to the brakes during testing, faithfully replicating situations of rain, snow, ice, or winter driving.

The Water Cart features an integrated PLC-based control system and an HMI (Human-Machine Interface), ensuring user-friendly management of all parameters. It includes a high-speed electric motor, a triple tank for different fluids, a state-of-the-art Keyence flow sensor, and an adjustable flow rate from 0.08 to 10 liters per minute. The system offers full compatibility with all nozzle types, automatic flow regulation, support for various liquids, and advanced features like snow simulation and connection to an atomizer. It can operate in three main modes: Tuning for calibration, Manual for direct control, and Automatic for full integration with the test bench.

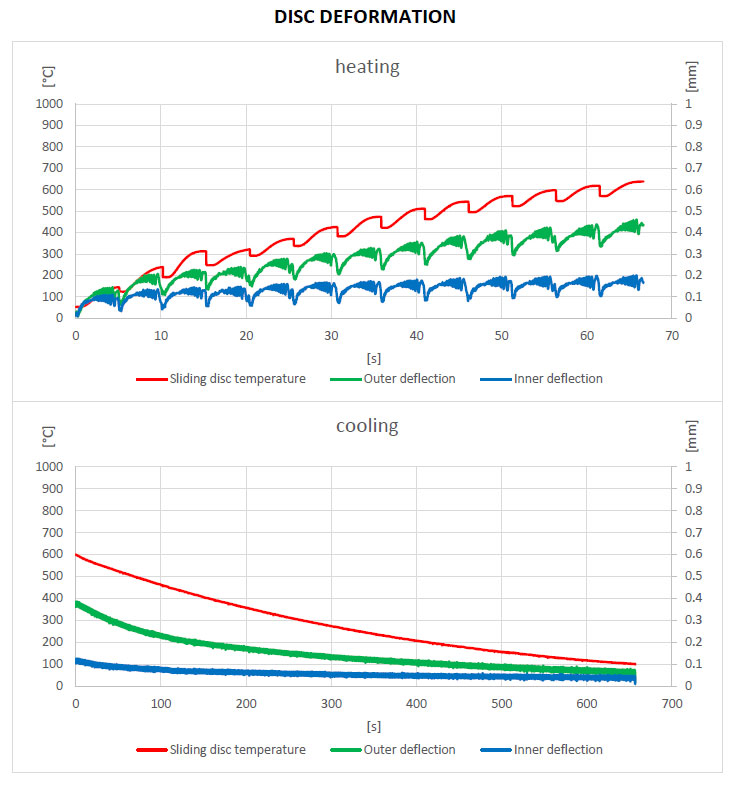

This functionality is essential for evaluating brake behavior in adverse conditions, determining the effectiveness of drying systems, and ensuring safety and reliability under all operating conditions. The precision and repeatability of our Water Cart make it an indispensable tool for manufacturers intending to validate their product performance worldwide. - Precision DTV (Disc Thickness Variation) System:

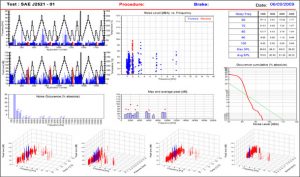

The DTV system is crucial for monitoring brake disc thickness variation during tests. We use high-precision sensors to continuously measure disc thickness at various points, detecting even the slightest variations caused by wear, thermal deformation, or other factors. Monitoring DTV is essential for assessing disc durability, identifying potential noise issues (brake judder), and optimizing design for greater stability and smoother braking. - Advanced NVH (Noise, Vibration, Harshness) System:

Driving comfort is a crucial aspect. Our NVH system allows us to analyze and quantify noise, vibrations, and harshness generated by the braking system. We use highly sensitive microphones, accelerometers, and advanced analysis software to identify critical frequencies, locate sources of noise and vibration, and assess the effectiveness of countermeasures. This enables us to help our clients develop quieter, more comfortable, and higher-performing braking systems.

Download the brochure - High-Precision Micrometric Balances:

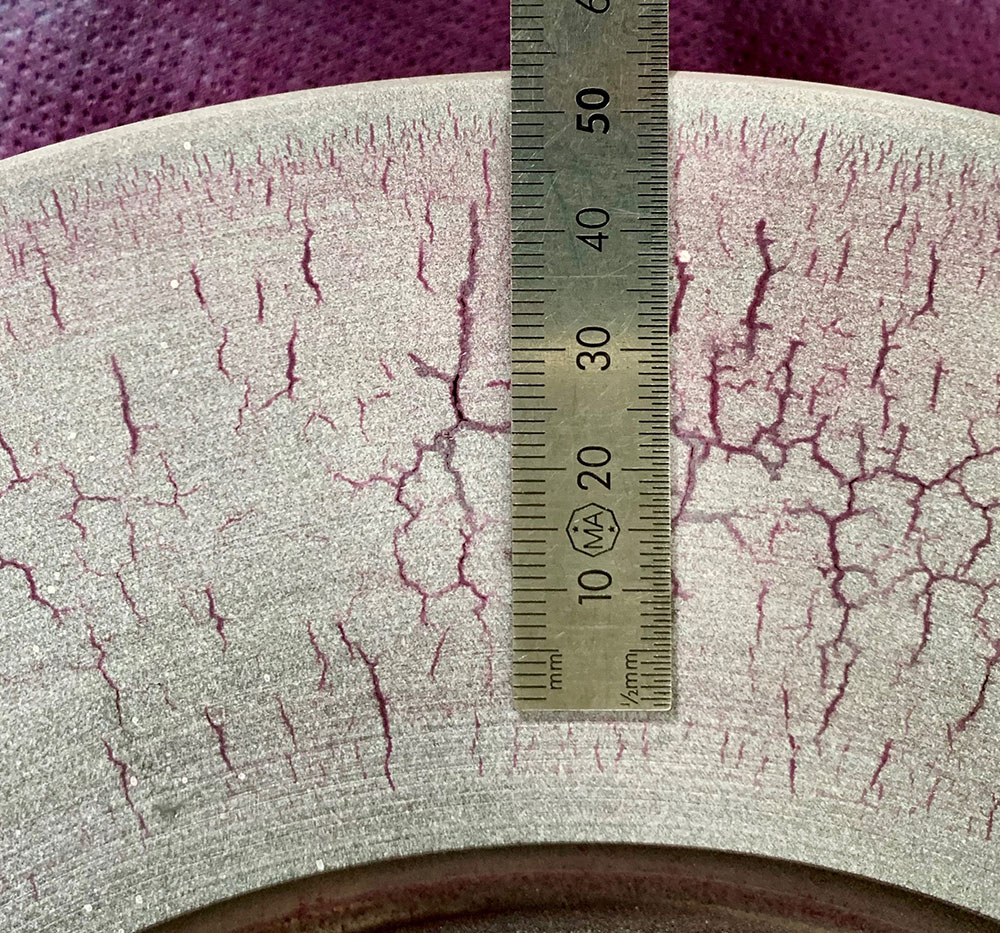

For accurate analysis of worn material and particulate emissions, we use micrometric balances in controlled environments. These balances allow us to measure with extreme precision the mass of pads, discs, and friction materials before and after tests, determining the wear rate and assessing component durability. The data obtained is fundamental for regulatory compliance and for developing more resistant and longer-lasting materials. - Penetrant Liquids for Defect Detection:

We use the penetrant liquid technique for detecting surface cracks and defects in brake components. This non-destructive method allows for the identification of even the smallest defects, guaranteeing material quality and integrity. Inspection with penetrant liquids is particularly useful for analyzing components subjected to high stress and for preventing premature failures. - EPB/EMB Trolley System

TecSA’s EPB/EMB Trolley System is a plug-and-play test trolley for Electric Parking Brakes (EPB) and Electro-Mechanical Brakes (EMB): it powers the brake from 0-120 V/200 A, communicates via CAN/CAN-FD with the customer’s ECU, and connects in real-time to the dynamometric test bench. In automatic mode, it executes force, torque, or ramp cycles commanded by the test bench; in manual mode, it allows for diagnostics and calibration. Ideal for dynamic, static, durability tests, and vehicle simulation with regeneration, guaranteeing precision, repeatability, and immediate integration into existing test lines. - Interface with Client-Specific Instrumentation:

We are capable of integrating our instrumentation with specific data acquisition systems or sensors provided by the client. This flexibility allows us to adapt to the particular needs of each project and guarantee compatibility with existing systems.

The Advantages of Choosing TecSA R&D

- Reliable and Repeatable Data: Our state-of-the-art instrumentation and rigorous procedures guarantee precise and reliable results.

- Specialized Technical Support: Our team of experienced engineers and technicians provides comprehensive support at every project stage, from test planning to results analysis.

- Customized Solutions: We are able to adapt our services to the specific needs of each client, offering tailored testing solutions.

- Regulatory Compliance: Our tests are performed in accordance with international standards and current regulations.

- Reduced Lead Times: Our operational efficiency and state-of-the-art instrumentation allow us to reduce the lead times for delivering results.

Contact Us: to discuss your specific testing needs and discover how TecSA R&D can help you achieve your goals, please do not hesitate to contact us.

Thermocameras

Spraying system on brake

DTV (Disc Thickness Variation) system

NVH system – download the brochure

Penetrating liquid